1. Mill finished

2. Powder coating: Bronze, black, white, etc

3. Anodized: Black, silver, bronze, golden, champagne, etc

4. Wooden Grain Customized color tone is provided

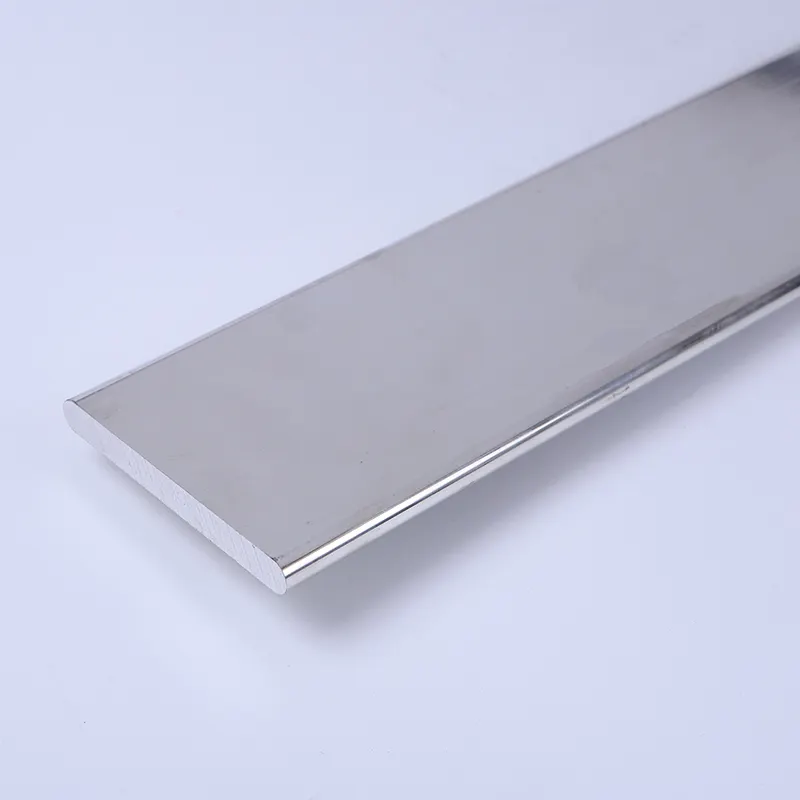

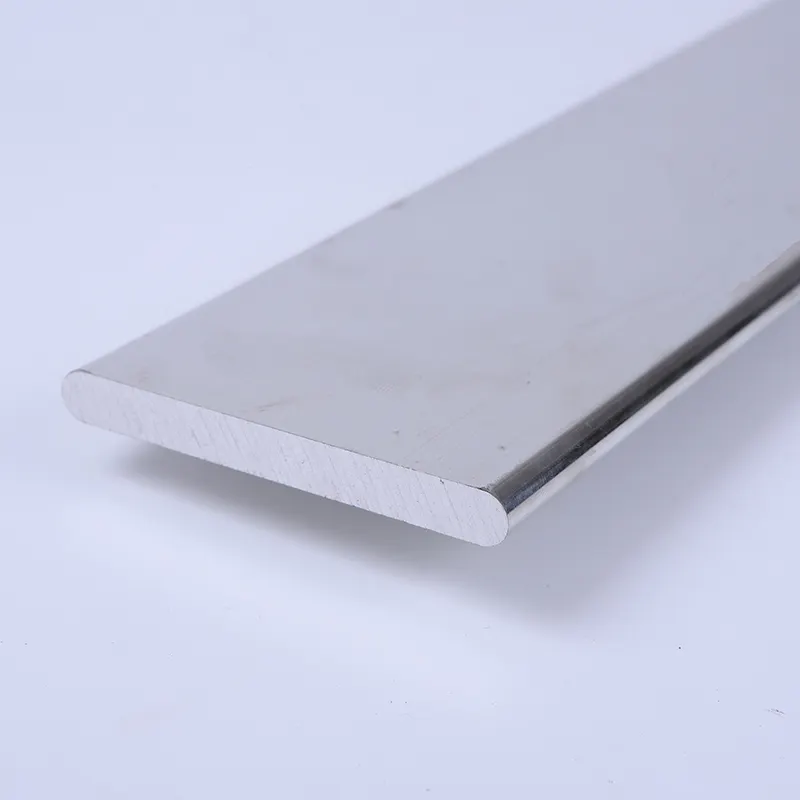

1. Hight brightness and hardness

2. Strong coated adhesion

3. Anti-scratch, smoothness

4. High weather resistance ,high corrosion resistance ,good wear resistance

1. PE Protective film , PE shrink film for each bundle

2. Customized Packaging requirement

3. More years' professional experience in research, manufacturing

4. Our modern deep processing center can provide machining such as Bending,

cutting, punching, drilling, etc.

ISO9001 / SGS /CE/ Other certificate which clients need

1. We operate the most strict quality control system, the detection is from

the material, production process

2. Die design →Die making →Extruding →Cutting →Heat Treatment→ QC →Surface treatment →QC →Packing →Shipping →After Sale Service

Advantages of tinning on aluminum bars

Improving corrosion resistance: Tin has good corrosion resistance, and tin plating can effectively prevent metal surfaces from being oxidized by air, thereby improving the lifespan of metal products.

Enhanced conductivity: Tin plating on the surface of aluminum bars can reduce the contact resistance of the overlap surface and enhance conductivity.

Prevent direct contact between aluminum bars and copper bars: The number of electrons around aluminum and copper atoms differs greatly, and copper and aluminum contact will form a contact potential, equivalent to contact resistance, which will generate heat when current flows through. Tin plating can prevent this electrochemical corrosion.

Advantages of tinning on aluminum bars

Improving welding performance: Tin plating has good stability in air and can provide good welding performance, making it easier to weld aluminum bars in subsequent processing.

Aesthetics and Decoration: Tin plating can make the metallic tone of the surface more beautiful, while maintaining uniformity and brightness, thereby maintaining a high level of color and surface smoothness.

In summary, tin plating on aluminum bars not only protects them from corrosion, but also improves their conductivity and welding performance, while increasing their aesthetic appeal.

Already have customer more than 30 countries and familiar with the quality demands.

Extruders from 800Ton~2000 Ton covered most dimensions of the Industry profiles.

CNC machining & Colorings.

STRONG R&D: Help customers finalize the design, strong tool design ability ,excellent pressing and surface treatment technology.

Strict quality management: ISO Administration system.

High capacity of manufacturing and wide range of products.

Be able to provide secondary fabricating.

Be able to provide one-stop supply solution.

Zhang jia gang Germao Aluminum Co., Ltd., was established in January 2016, with a total investment of over 70 million Yuan. It is a professional manufacturer of industrial aluminum profiles. The company is located in the national city -Zhangjiagang city, which is close to Zhangjiagang port and shanghai port, adjacent to the highway, land and water transportation is very convenient. It covers an area of 18,000 square meters and plant area of 10,000 square meters.

Germao possess nearly 10 experienced senior engineer and technician, 10 quality inspection personnel. The company is equipped with six sets of extrusion machines (800T/1250T/2000T), Supporting the sawing machine, punch, drilling and other procession equipment and surface treatment production lines. We can produce aluminum profiles with material of 6063, 6061, 6005, 6082, 3003, 7003, 5052 etc. The company has passed ISO9001 and ISO/TS16949 certification.

At Germao, we could supply you one-stop service from the research and development to the finished products. The products are widely used in cars, solar panel industry, sanitary ware industry, bicycles, medical devices, heat sink industry,electrical equipment, ladders, scaffolding, mushroom houses and other industries.

“Quality first” is our production philosophy .The products are strictly manufactured comply with National Standard of Aluminum production. “Honesty and truth-seeking” is our pursuit,we will provide you products with reliable quality fast delivery and superior after-sales service to achieving common development and creating our brilliant tomorrow together.

Factory And Work Environment

1

What Is Custom Aluminum Extrusion?

Custom aluminum extrusion is a process of creating specific shapes and lengths of

aluminum products based on a customer's design or requirements. This is achieved by heating up an aluminum extrusion billet and forcing it through a die or mold to create the desired shape.

2

What Are The Advantages Of Using Custom Aluminum Extrusion Profiles?

The advantages of using custom aluminum extrusion profiles include the ability to create unique and complex shapes, lightweight and strong material properties, excellent corrosion resistance, and high thermal conductivity. Additionally, these profiles can be produced in high volumes at a relatively low cost, making them ideal for mass production applications.

3

What Types Of Applications Are Custom Aluminum Extrusion Profiles Used For?

Custom aluminum extrusion profiles can be used for a wide range of applications, including construction, transportation, aerospace, electronics, industrial machinery, and consumer goods. They are commonly used for creating frames, enclosures, panels, railings, and other structural components.

4

What Are The Available Finishes For Custom Aluminum Extrusion Profiles?

The available finishes for custom aluminum extrusion profiles include anodizing, powder coating, painting, and polishing. These finishes can enhance the appearance, durability, and performance of the aluminum profile, providing a high-quality finish.

5

What Is The Typical Lead Time For Custom Aluminum Extrusion Profiles?

The typical lead time for custom aluminum extrusion profiles varies depending on the complexity of the design, the order quantity, and the availability of raw materials. Typically, lead times can range from several weeks to a few months. However, some aluminum extrusion manufacturers may offer expedited services to reduce lead time.

6

What Is An Aluminum Extrusion Supplier?

An aluminum extrusion supplier is a company that specializes in producing and supplying aluminum extrusion profiles and related products to commercial and industrial clients. These suppliers typically offer a wide range of sizes, shapes, and finishes to meet customer's specific requirements.

7

What Are The Benefits Of Using An Aluminum Extrusion Supplier?

The benefits of using an aluminum extrusion supplier include access to a wide range of high-quality aluminum extrusion products, reduced manufacturing costs, and faster production times. Additionally, suppliers can help customers with technical support, design, and development of customized products.

8

What Is The Difference Between Standard And Custom Aluminum Extrusions?

Standard aluminum extrusions are pre-designed profiles that are readily available in a range of sizes, shapes, and finishes. Custom aluminum extrusions are created based on a customer's specific design requirements and may involve complex shapes, special finishes, and other unique features.

9

How Do I Choose The Right Aluminum Extrusion Supplier?

The right aluminum extrusion supplier should have a track record of excellent quality and customer service, a wide range of products and capabilities, competitive pricing, and fast lead times. Additionally, they should be willing to work collaboratively with the customer to understand their needs and provide personalized solutions.

Company Advantages

· Zhangjiagang Germao Aluminum Co., Ltd.,'s R&D engineers seek the most durable hardware materials for aluminium extrusion manufacturers.

· The product has a superior quality and has got relative quality certificates.

· Through years of efforts, Germao now has been developing into a professional director in aluminium extrusion manufacturers industry.

Company Features

· Being a widely-recognized manufacturer in China, Zhangjiagang Germao Aluminum Co., Ltd., mainly focuses on the design and production of aluminium extrusion manufacturers.

· Our company has well-trained and highly-skilled employees. They can perform tasks much faster because they know what they’re doing and the quality of work will also improve.

· Our company put much emphasis on its social responsibility. From the perspective of the most obvious point, we assume strict requirements regarding employees' welfare. This action will boost employees' morale and improve greater productivity eventually. Get more info!

Application of the Product

Germao's aluminium extrusion manufacturers is widely used in various industries and fields.

We work hard to develop solutions that best meet the needs of our customers based on their actual situation, so as to help each customer succeed.